Eti Alüminyum A.Ş. Seydişehir İşletmesinde yer alan tesisler;

• Oymapınar HEPP

• Antalya Import – Export Directorate

• Directorate of Mining

• Alumina Factory,

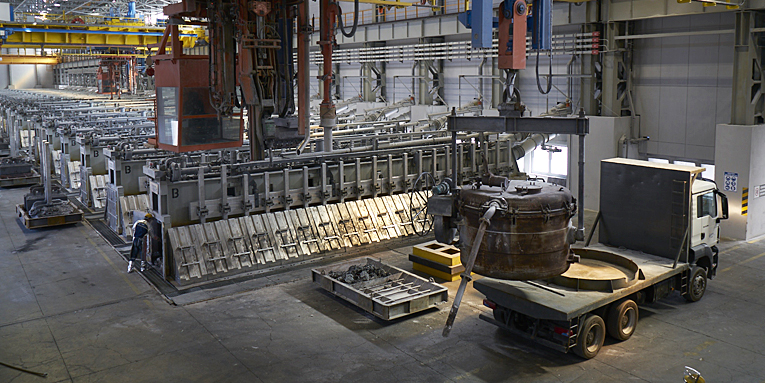

• Raw Aluminium Factory ( Electrolysis and Anode Production Plant),

• Foundry,

• Rolling Plant,

• Machinery & Equipment Plant,

• Directorate of Energy,

• Directorate of Auxiliary Operations,

• Directorate of Quality Control and R&D,

• Directorate of Management Systems and Study Control

• Directorate of Equipment Operation, Maintenance & Repair

• Directorate of Information Processing,

• Directorate of Accounting and Financial Affairs

• Directorate of Machinery Supply and Purchase

• Directorate of Sales and Marketing

• Directorate of Human Resources

• Directorate of Administrative and Social Affairs

• Directorate of Environment

• Directorate of 2nd Group Maintenance & Repair

• Directorate of Transport

• Workplace Physician’s Department

• Department of Investment Group